Your energy bills drop. Not by a little—by 50% or more compared to running separate heating and cooling systems. That’s real money back in your operating budget every single month.

Your facility stays comfortable year-round. No more juggling two different systems or dealing with inconsistent temperatures across different zones. One heat pump handles both heating and cooling, adjusting quickly when San Antonio weather swings from one extreme to another.

Maintenance gets simpler. Instead of servicing separate furnaces and AC units, you’re maintaining one system. Fewer service calls. Fewer things that can break down. Less time coordinating with technicians and more time focusing on your actual business.

The system lasts longer too. Commercial heat pumps typically run 15 years or more with proper care—outlasting traditional systems that wear out faster from constant cycling. You’re looking at better return on investment and fewer replacement headaches down the road.

Texas Air Repair is a veteran-owned company that’s been handling commercial HVAC work across San Antonio, Houston, and Austin since before heat pumps became the standard everyone talks about now. We know what works in Texas heat and what doesn’t.

Randolph AFB and the surrounding area present specific challenges. Military facilities need systems that won’t quit during peak demand. Commercial properties near the base need reliable service that understands tight schedules and operational requirements.

That’s why we offer 24/7 emergency service. When your heat pump goes down at 2 AM or over a weekend, you can’t wait until Monday morning. Our certified technicians respond fast because we understand that your facility’s comfort directly affects your mission—whether that’s serving military personnel, running a business, or managing a commercial property.

First, our technician evaluates your facility. Not a sales pitch—an actual assessment of your space, existing infrastructure, heating and cooling loads, and what your operation requires. Square footage matters. Insulation levels matter. How many people occupy the space and when they’re there matters.

Based on that evaluation, you get a recommendation for the right-sized system. Too small and it runs constantly trying to keep up. Too large and it cycles on and off too frequently, wasting energy and wearing out faster. Proper sizing is the difference between a system that works and one that becomes a headache.

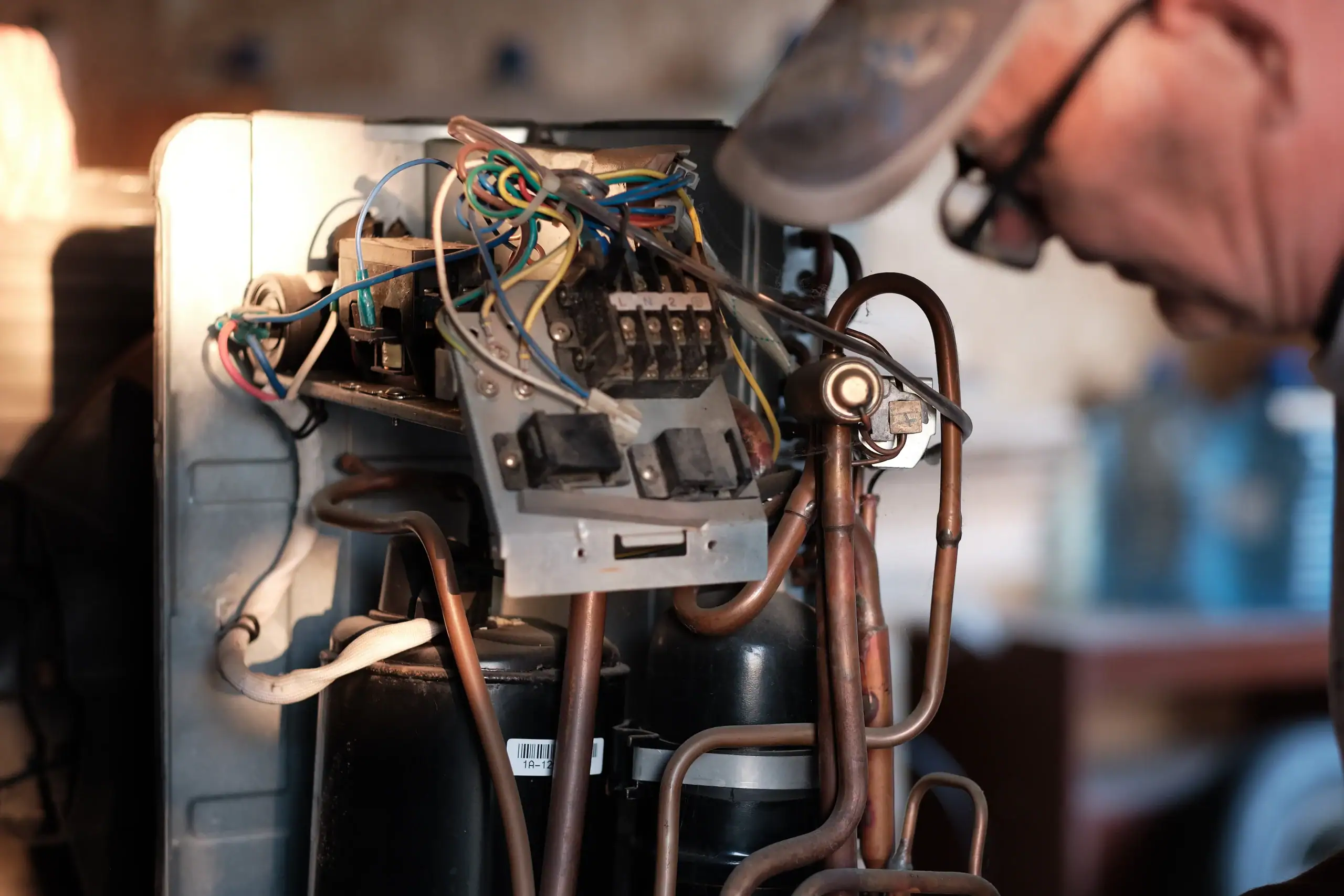

Installation happens with minimal disruption to your operations. The outdoor unit gets positioned where it has proper airflow and access for future maintenance. Indoor components connect to your existing ductwork or new distribution system if needed. Electrical connections are made to code. Refrigerant lines are installed and tested.

Once everything’s in place, the system gets tested under actual operating conditions. Airflow is measured. Temperatures are verified across all zones. Controls are programmed for your specific schedule and comfort requirements. You’re walked through basic operation and maintenance expectations before our crew leaves.

After installation, regular maintenance keeps everything running efficiently. That means filter changes, refrigerant checks, electrical connection inspections, and cleaning of coils and components. Most commercial operations schedule service at least annually, though heavy-use facilities benefit from quarterly visits.

Ready to get started?

You get a commercial heat pump system designed for your specific building—not a one-size-fits-all solution that sort of works. The system is sized based on your facility’s actual heating and cooling demands, taking into account San Antonio’s climate where summer temperatures regularly hit triple digits.

Energy efficiency is built in. Modern commercial heat pumps transfer heat instead of generating it, which is why they use 50-75% less energy than traditional systems. In Randolph AFB’s climate, where cooling dominates most of the year, that efficiency translates to substantial cost savings on your monthly utility bills.

The system provides both heating and cooling from the same equipment. When winter arrives and temperatures drop, the heat pump reverses its operation to extract warmth from outdoor air and move it inside. No separate furnace needed. No switching between systems or coordinating different service schedules.

You also get access to 24/7 emergency service. Commercial facilities can’t afford extended downtime when HVAC systems fail. Whether it’s a weekend, holiday, or middle of the night, our certified technicians respond to keep your operation running. That’s particularly important for facilities serving military personnel or businesses where climate control affects productivity and customer comfort.

Regular maintenance is included in service plans designed for commercial operations. Preventive care catches small issues before they become expensive repairs. Filters get changed on schedule. Refrigerant levels stay optimal. Electrical connections remain tight. Components get cleaned and lubricated. This ongoing attention extends equipment life and maintains peak efficiency throughout the system’s 15+ year lifespan.

Commercial heat pumps typically reduce energy consumption by 50-75% compared to running separate heating and cooling systems. The exact savings depend on your facility size, usage patterns, and the system you’re replacing.

For perspective, traditional electric resistance heating uses direct electricity to generate heat—expensive and inefficient. Heat pumps transfer existing heat from one place to another, which requires far less energy. In cooling mode, they work similarly to air conditioners but with better efficiency ratings.

A facility in Randolph AFB running an older HVAC system might see monthly utility bills drop by several hundred to several thousand dollars after switching to a modern heat pump. The payback period typically runs 7-10 years, but the system itself lasts 15+ years with proper maintenance. That means years of net savings after the initial investment pays for itself. Energy costs in Texas fluctuate, but heat pumps provide more predictable expenses because they use less power regardless of rate changes.

Most commercial heat pumps need professional maintenance at least once per year, though facilities with heavy usage benefit from quarterly service visits. The frequency depends on how hard your system works and what your facility demands.

Annual maintenance typically includes filter replacement, refrigerant level checks, electrical connection inspection and tightening, coil cleaning, airflow measurement, and thermostat calibration. These tasks prevent the 25% efficiency loss that comes from neglected maintenance—which means skipping service actually costs you money in higher energy bills.

Between professional visits, your facility staff should handle basic upkeep. Change or clean filters every one to three months depending on air quality and usage. Keep debris and vegetation clear around the outdoor unit. Check that vents and registers inside aren’t blocked. Monitor the system for unusual noises or performance changes that might signal developing problems. Catching issues early prevents expensive emergency repairs and extends equipment life well beyond the typical 15-year lifespan.

Yes. Modern commercial heat pumps are specifically engineered to operate efficiently even when San Antonio temperatures hit triple digits during summer months. Texas actually has more heat pumps installed than any other state—they’re designed for this climate.

Heat pumps work by transferring heat from inside your facility to the outdoors. Even when it’s 105°F outside, the system can effectively move heat out of your building because it’s using refrigeration principles rather than trying to “create” cool air. The outdoor unit’s compressor and fan are built to handle sustained high temperatures without failing.

The key is proper sizing and installation. An undersized system will struggle on the hottest days. An oversized system will cycle on and off too frequently, reducing efficiency and comfort. That’s why we evaluate your specific facility before recommending equipment—square footage, insulation, window exposure, occupancy, and internal heat loads all factor into selecting the right capacity. With correct sizing, your heat pump will maintain comfortable temperatures throughout even the most brutal Texas summer while using less energy than traditional cooling systems.

Commercial heat pumps typically last 15 years with proper maintenance, though well-maintained systems can run 20 years or longer. The lifespan depends heavily on usage intensity, maintenance consistency, and installation quality.

Air-to-air heat pumps (the most common type) average 15 years. Water-source and ground-source systems last even longer—often 19-25 years—because they operate under more stable conditions. Compare that to traditional HVAC systems that might need major repairs or replacement around the 10-12 year mark.

The difference comes down to how the equipment operates. Heat pumps transfer heat rather than generating it through combustion or resistance heating. This creates less wear on components. However, neglecting maintenance accelerates deterioration. Dirty filters force the system to work harder. Low refrigerant levels strain the compressor. Loose electrical connections create resistance and heat. Regular professional service addresses these issues before they cause premature failure. Most commercial facilities that follow recommended maintenance schedules see their heat pumps outlast the 15-year average, which improves return on investment and reduces the frequency of expensive replacement projects.

Yes. We provide 24/7 emergency service for commercial heat pump repairs throughout the Randolph AFB and San Antonio area. Commercial facilities can’t afford to wait until regular business hours when HVAC systems fail.

Emergency response means a certified technician is available any time—weekends, holidays, middle of the night. When your heat pump goes down during a Texas summer heatwave or fails unexpectedly during operating hours, you need immediate help. The longer your facility goes without climate control, the more it affects your operations, employees, and customers.

Our emergency service includes diagnosis, repair, and temporary solutions if parts need to be ordered. Most common issues can be resolved on the first visit because our technicians carry standard components and have access to supplier networks for specialized parts. For facilities serving military personnel or operating on tight schedules, this rapid response minimizes disruption and prevents the cascading problems that come from extended HVAC downtime. The goal is getting your system back online as quickly as possible so your facility can resume normal operations.

Heat pump sizing requires evaluating your facility’s actual heating and cooling demands—not just square footage. A proper assessment considers building size, insulation quality, window exposure, ceiling height, occupancy levels, internal heat sources, and local climate conditions.

Our technician calculates your facility’s heat gain and loss. How much heat enters during summer through windows, walls, roof, and internal sources like equipment and lighting? How much heat escapes during winter? This determines the capacity needed, measured in tons or BTUs. Generally, you need about 20,000-24,000 BTU per 1,000 square feet, but that’s just a starting point.

Undersizing causes problems. The system runs constantly trying to maintain temperature, wearing out faster and driving up energy costs. You’ll notice uncomfortable hot or cold spots and inadequate humidity control. Oversizing creates different issues—the system cycles on and off too frequently, never running long enough to properly dehumidify air or operate efficiently. In Randolph AFB’s climate where humidity can be high, proper sizing ensures both temperature and moisture control. We conduct on-site evaluations to get sizing right the first time, preventing the comfort and efficiency problems that come from incorrect equipment selection.

Other Services we provide in Randolph Afb